Digitizing Paper-Doll Plans for Concrete Tilt-Up Construction

December 6, 2021

Concrete TiltUp panels are poured on-site, typically on the floor slab towards the interior of the building. The construction team needs to know exactly where they will place formwork and layout the panels to be poured on the slab before safely and efficiently lifting the panels into final position.

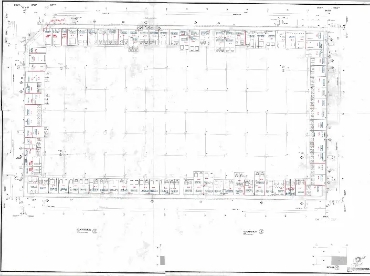

Panel geometry, panel weight, crane path and crane capacity all drive where panels will be cast before construction. Project Managers oftentimes cut out scaled pieces of paper that represent each of the TiltUp panels on the project. These pieces of paper are then manually placed and taped onto a larger printed plan drawing of the building. Project Managers will sometimes even have to stack panels to get them as close to their final position while also optimizing the panel layout and formwork. Some project managers can take up to 2 to 3 days to do all of this work. When they are all done, they have to take this large taped together plan and get it digitized on a large specialty scanner so it can be emailed to the rest of the team. This 2D plan tends to leave out a level of detail of how tight panels will actually be out on site and visualizing what panel bracing will look like as panels are erected in a certain order.

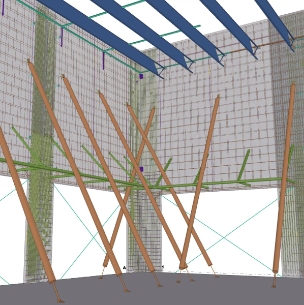

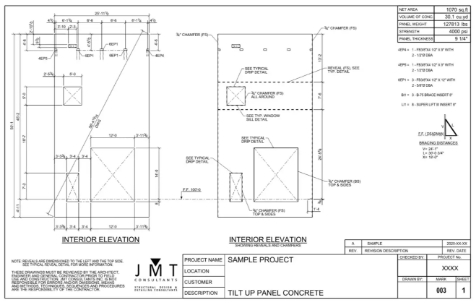

Here at JMT Consultants, we create a detailed 3D digital model of all the panels on a project in order to create erection and panel book drawings and lifting design for the construction team in the field. This 3d model includes openings, reveals, edge chamfers, embeds, inserts, panel braces, and even reinforcement. All of the connection interfaces with the cast in place footings and slab as well as structural steel framing into the walls, are all modeled together in one environment. Thus preventing clashes and connection mismatches.

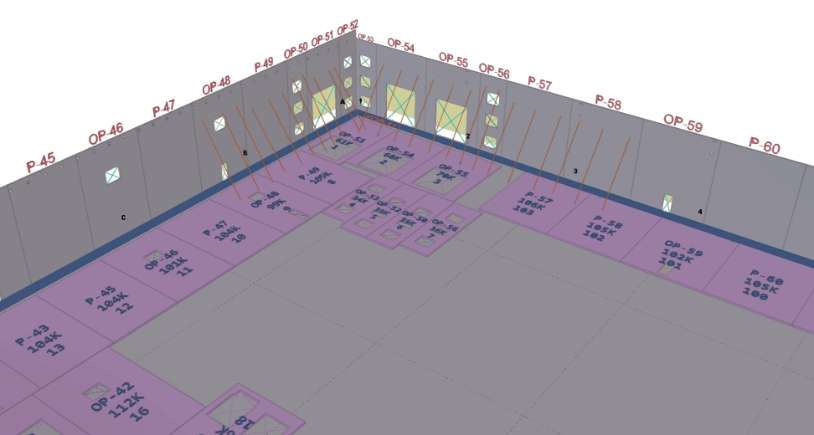

We discovered that this rich 3D model contains everything required to do the panel layout for our concrete construction clients. So rather than just providing panel books and erection drawings, JMT can quickly layout the vertical in position panels on the floor slab in the digital model in minutes without any printing, cutting, or taping required. If the design changes and the model updates, then the layout plan can be easily adjusted in the 3D model. A 2D plan drawing that looks like the traditional Paper Doll Plan can be automatically extracted from the 3D model for the field and emailed to the project team as a PDF file. Take a look at this 10 minute video to see a live demonstration of this unique process JMT delivers to its clients.

Not only can we expedite the creation of the Panel Layout Plan, we can publish this 3D model to be used by the jobsite and project manager on their mobile devices using Trimble Connect. The field can rotate to any location or orientation to visualize exactly how the panels should be placed out in the field and the exact order in which they should be constructed.

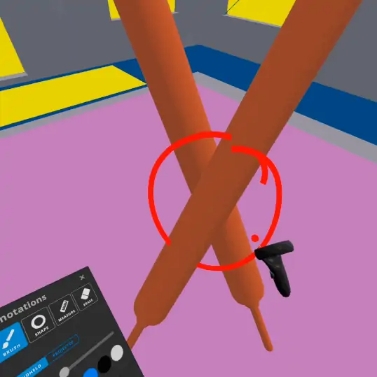

The project team can also immerse themselves in a live sized virtual reality environment using the Oculus Quest headsets and collaboration software, Prospect by IrisVR. Here are a couple of images from our detailing project manager in one location wearing an Oculus Quest virtual reality headset collaborating live across the country with a detailer to discuss potential construction issues. In this case, both parties were able to see a clash in real life scale and talk live in a digital jobsite. Not only could they see the issue together, they could redline it and take snapshots to be automatically sent to their desktop computers to make the change. Being immersed in this life size virtual environment is much more powerful at catching sequencing and construction clearance issues compared to a 2D Paper Doll Plan alone.

If you’d like to save time and catch problems before getting on site, contacts us and we’d be happy to show you how.